Welcome to Moda Fabrics!

On point...

On point...

In the law, cases are "on point" when the facts of the case in the law books - already decided - exactly match the facts in your case so you can cite it as being the law.

So it follows that it kind of annoys me when folks use the phrase "case in point"... where does that come from? It's like "tough road to hoe" instead of "tough row to hoe". But then I get persnickety about silly stuff like that. You're shocked, I know.

But I digress - another big shock.

Oh - Happy Monday!

This is a Tip Jar post and it's about those pointy things we use every time we stitch - needles.

Are you changing your sewing machine needles regularly?

You know you should, right? Whew. But here's the problem - what is regularly? And how do you remember when you changed it the last time?

I happily confess to thinking that you only changed sewing machine needles when they broke - usually by sewing over a pin or something silly like that. When the sewing machine folks started saying they should be changed regularly, I thought it was a collaborative conspiracy - legal term: collusion - with the sewing machine needle manufacturers to get us to buy more needles. Since I was still young and impressionable, I bowed to their pressure and - this pains me greatly - discovered that I could tell the difference.

I really don't like when "the man" is right.

The reasoning is simple - that needle is traveling very fast and it is piercing fabric every one of the couple hundred times it passes through the fabric in a minute. (If you have a Juki, it's a thousand times per minute.) It stands to reason that the constant hitting of the fabric will slowly dull the tip of the needle. But how often should you change it? Every four hours? Every eight? And even if there were a definitive, conclusive answer, how do I remember when that was?

I backed into a system that works for me. That last part is the most important - it comes with no guarantees or factual evidence to support it's reasoning. Which probably explains why it works for me...

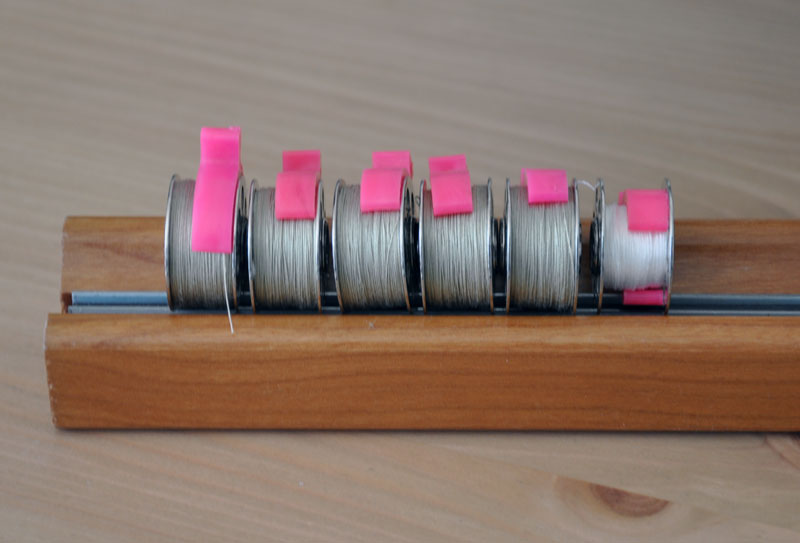

I change my needle every five bobbins. It's nothing more than a mile-marker.

Side note - while those bobbin-buddies are cute, they also serve a really good purpose beyond keeping the thread from un-winding. If you keep your extra wound bobbins on the top of your machine - which I sometimes do when I'm at a retreat - the thread from the bobbin can get caught up with the thread spool winding into the machine. It doesn't happen often but it's a mess when it does, and I'm told that it can do harm to your machine.

When I'm winding my new bobbins and changing the needle, I also clean and oil my sewing machine. Yes, I do that every single time.

Unless I have just a little bit more to finish the pieces, blocks, borders I need to finish before shutting it all down for the night... just saying.

Flashback - I was sixteen when my parents gave me a Bernina 830 for Christmas. I wanted a car but my parents decided - correctly so - that I would be far better off operating a machine with a foot pedal/gas pedal if it didn't have four wheels. (My parents were pretty smart that way.) When I took the guide classes for my machine, the very first thing I was taught was how to take apart, clean and oil my machine. Maintenance before operation. (It might be why I still have that machine... almost 13 years later... :::snort:::)

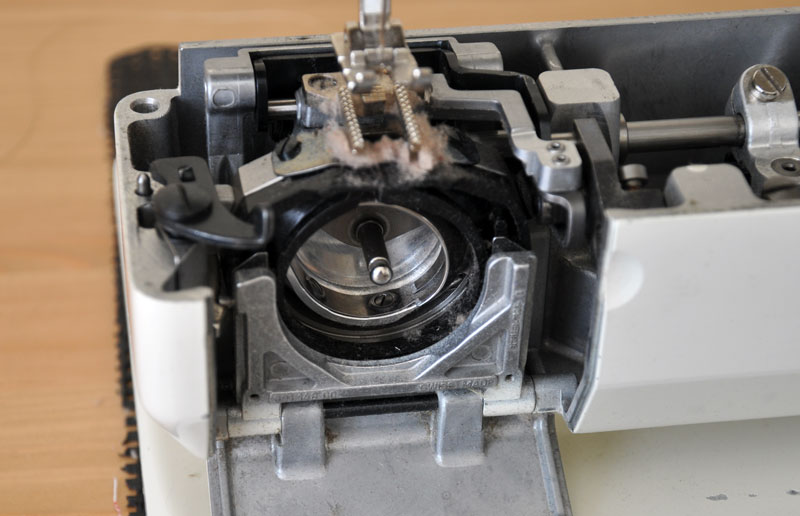

This is how much lint can accumulate after just four bobbins - I needed the picture. (And yes, I still took the time to clean and oil the machine since it was open and I needed wound bobbins for the picture. Compulsion, thy name is Carrie.)

Changing the needle and machine maintenance are about achieving the same goal - prolonging the life of your machine. The harder it has to work, the sooner it will wear out. All of our machines are different and many newer machines don't require regular oiling. If your machine doesn't require that, I recommend that you find some kind of mile-marker to let you know when it's time to change the needle. A friend whose machine doesn't need to be oiled regularly buys pre-wound bobbins and puts them in one of those donut-rounds - called a BobbinSaver - for bobbins. Every sixth bobbin is empty to remind her that it's time to change the needle and blow out the lint in her machine.

By the way... blowing the lint out. Can we take a moment and talk about canned air? The sewing machine repair folks will tell you it's a bad, horrible, potentially disastrous idea. I get that - really. If I opened up my machine and didn't take the time to brush out that big clump of lint, I can see that some might get blown into a crevice instead of out. Got it. But this I know for sure... I have been using canned air to clean my Bernina for more than 20 years - ever since you could start buying the canned air at camera shops. Do I recommend it? No. Do I do it anyway? Yes.

And that's it for today. This message has been brought to you by the fine people at Schmetz Needles. I'm kidding!

I still there's some kind of conspiracy at work... it's the only reason for making the eyes smaller.

You know they've made them smaller, right?

Comments